Jiangsu Chaoyue Agricultural Development Co., Ltd. is a wholly-owned subsidiary of Jiangsu Lujiangnan Food Group, which settled and registered in Taixing Agricultural Products Park in June, 2018. At present, the first phase covers an area of 30 mu with an investment of nearly 200 million yuan. Upon being put into operation in 2020, it will become a digitally intelligent factory for Chinese sauce-brined meat products, featuring the largest workshop area, the most comprehensive innovation, a high degree of semi-automation, and leading technological processes. The designed annual processing capacity is 15,000 tons of sauce-brined meat products and 5,000 tons of convenient dishes. The expected output value is guaranteed to be at least 800 million yuan, with a target of striving for 1 billion yuan.

--From Entrepreneur Daily

Initiating Cooperation to Enhance Competitiveness through Innovative Logistics

Based on the demand for innovative logistics, cost reduction and efficiency, in 2019, Lujiangnan officially established a partnership with Zhongding Integration to build a flexible, information-based, and automated food & cold chain intelligent logistics and warehousing system.

Customized Food & Cold Chain Intelligent Logistics Warehouse System

The food & cold chain intelligent logistics warehouse is 20 meters high, with a temperature of -20℃. It includes the stacker crane system, shuttle system, conveyor system and software management system.

PART 1

Stacker Crane & Shuttle System

After linking material and pallet information, the code reader scans the code, and the conveyor system transports the pallet of finished goods to the conveyor position at the aisle entrance. The stacker crane receives the command to pick up the pallet and place it at the designated aisle entrance. The shuttle inside the aisle transports the pallet to the designated storage location.

Shape detection device and weight detection device are set up at the inbound port. Pallets with abnormal width and height dimensions, or pallets with deviation between actual weight and theoretical weight will trigger alarm and be withdrawn from the inbound port, and can be re-stored into the warehouse only after manual confirmation.

PART 2

Seamless Connection between Warehouse and Workshop

According to the outbound order, the system sends out the outbound instruction. The stacker cranes cooperate with the shuttles to take out the pallets and transport them to the aisle entrance, the conveyor system transports the pallets to the whole-pallet outbound entrance, and then sends the corresponding pallets to the workshop of 1F, 2F, and 3F through the RGVs and the lift to realize the seamless connection between the warehouse and the workshop.

PART 3

Outbound Process of Empty Pallet

When the empty pallets in the receiving area are used up, pressing a single button can retrieve one or several empty pallets to the outbound port.

Software Management System

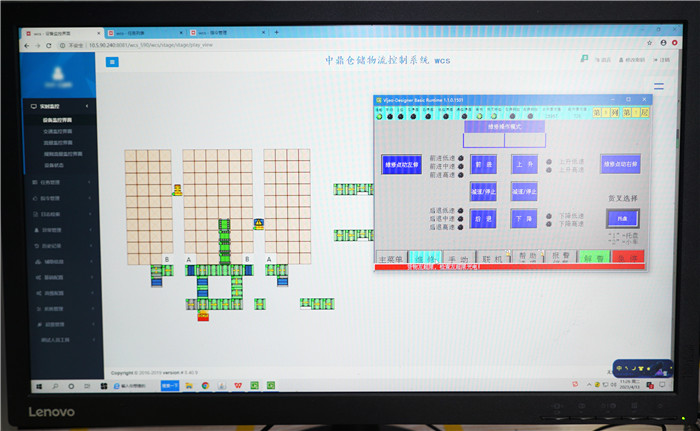

Configure WMS (warehouse management system) and WCS (warehouse control system), which can realize automatic and seamless connection with ERP system of Lujiangnan. Both sets of software management systems have their own servers and databases, and are independent information/data management and control systems, capable of realizing monitoring, inbound and outbound management, querying, maintenance, etc. By creating an operating platform, it reduces the difficulty of the work of the logistics staff, and improves the precision and accuracy of the warehousing and logistics.

Digitalized and Intelligent Factory + Lujiangnan's Original Taste Competes in the Market

With the food & cold chain intelligent warehousing and logistics system tailored by Zhongding Integration, Lujiangnan has successfully realized the standardization and intelligence of product logistics to achieve cost reduction and efficiency increase while maintaining its unique flavor.

Zhongding Integration has been deeply involved in the food and cold chain industries for over a decade, possessing mature capabilities in constructing intelligent cold storage facilities in environments as low as minus 25 degrees Celsius. This ensures that we can fully meet the unique business models and logistics requirements of food and cold chain enterprises.

In this case, Lujiangnan has reached the goal of building a digitalized and intelligent factory. It is believed that in the future ahead, Lujiangnan will stand firm in the increasingly fierce food market with strong corporate creativity and competitiveness!