Shandong Huifa Foodstuff Co., Ltd. (hereinafter referred to as "Huifa Foodstuff") was formally established in 2005, covering an area of more than 400,000 square meters, and is committed to building a "central factory" for Chinese catering enterprises. It has now formed eight series of products, including meatballs, seasoned products, shallow-fried products and high-end customized gift boxes. Huifa Foodstuff currently has nine subsidiary companies. In 2017, Huifa Foodstuff was listed on the Shanghai Stock Exchange (stock code: 603536), successfully landing on the A-share main board.

In 2019, Zhongding Integration and Huifa Foodstuff worked together to jointly build a food & cold chain intelligent storage center, which links the production and logistics seamlessly with intelligence to help the enterprise improve logistics value, reduce costs and increase efficiency!

Food & Cold Chain Intelligent Logistics System

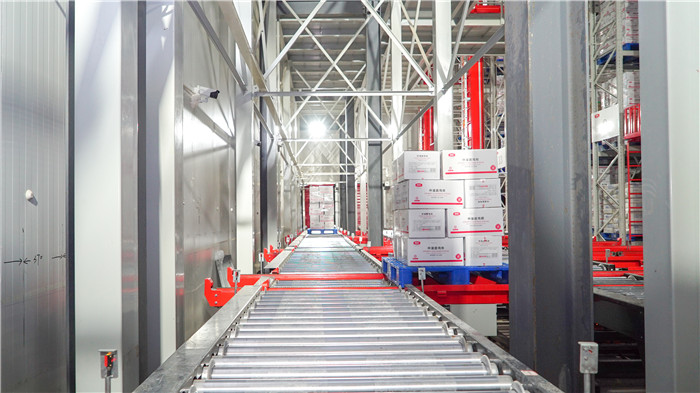

The solution for the whole set of intelligent logistics system is: storage temperature of -18~-22℃, including 5 double-column stacker cranes of 13.9 meters high by Zhongding Integration and hundreds of units of conveyor equipment, 10,812 cargo spaces, mainly for raw materials and finished products. The system can realize functions such as warehousing, conveying, picking, data acquisition, real-time monitoring, and remote control.

Full-process Intelligence and Automation

Storage of Finished Products and Raw Materials on Goods Platform

The entire pallet is transported to the platform of the three-dimensional warehouse, and undergoes inspection with dimension measurement devices. If the goods fails the inspection, it will be returned for product sorting; if it passes, it will be transported to the inbound point of corresponding aisle for warehousing.

Storage of Finished Products from Workshop U1U2U3

Finished products of U1U2U3 workshop are transported to the conveyor line before the warehouse by lift and RGV shuttle, and put to the designated cargo space by stacker cranes to complete the inbound process.

Raw Materials from Warehouse to Workshop

After receiving the instruction from the upper-level system (ERP or MES), the stacker cranes will transfer pallets with raw material to the outbound port through the pre-storage conveyor system to complete the inbound process. Upon the raw materials being used up, the empty pallets will be put back to the pallet conveyor line to complete the process of returning to warehouse.

Outbound of Finished Products

After receiving the instruction from the upper-level system, the stacker cranes will transfer the finished goods to the outbound port through the conveyor system to complete the outbound process.

Half-pallet Picking for Return to Warehouse

After the completion of picking, the goods are transported from the picking point to the semi-pallet goods dimension measurement device through the conveyor system. After passing the inspection, they are returned to the warehouse once again.

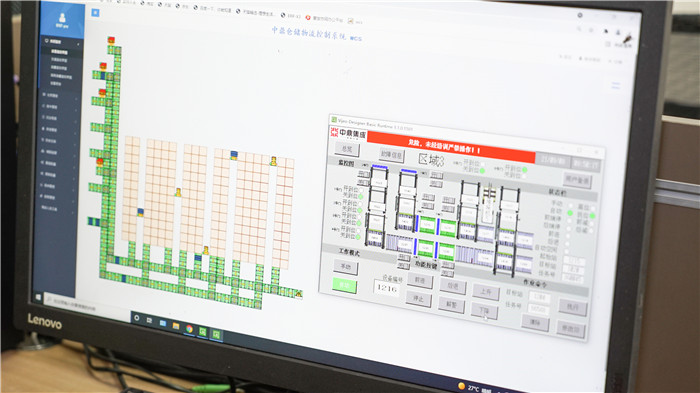

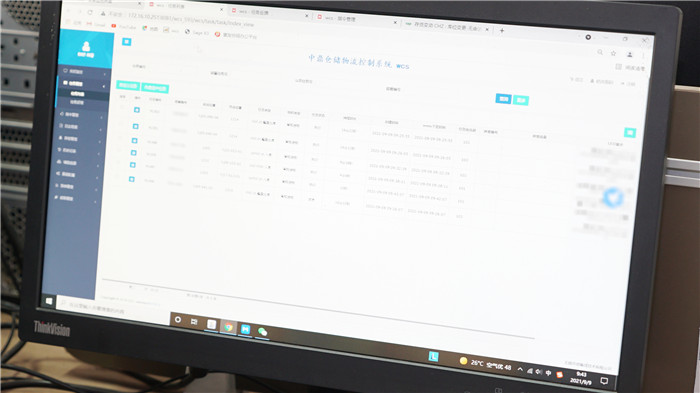

Software System Realizing Efficient Information Interconnection

The solution for the entire logistics system also adopts the advanced intelligent logistics software management system such as WCS and WMS, developed by Zhongding Integration independently, which can realize the comprehensive management of materials, cargo space and information storage, and seamlessly connect with the enterprise resource management system (ERP) through the specially-developed interface program to ensure efficient interconnection of enterprise information.

Meanwhile the complete set of intelligent logistics software management system has its own server and database, ensuring the independent management and control of logistics information and data.

The intelligent warehouse creates a more efficient and flexible logistics service for Huifa Foodstuff through automated and informatized logistics management means, and promotes the enterprise to step into a new stage of development!

As a leader in the field of food & cold chain logistics, Zhongding Integration has provided services to many famous food and cold chain enterprises, such as Anjoy Food, Guolian Aquatic Products, Henan Xianyi, Shandong Fovo Foods, Jingu (subsidiary of XMXYG), Sanquan, COFCO, Shuanghui, etc. In the future, Zhongding Integration will continue to make unremitting efforts in the field of intelligent logistics, provide more customers with advanced, high-quality and forward-looking intelligent logistics system solutions, and lead the intelligent upgrading!