Large automobile manufacturing enterprises are generally provided with the vehicle body intelligent logistics system that is a pivotal hub of all production links. The full-process intelligent logistics system that is unmanned and flexible is able to effectively increase output capacity and economic benefits for automakers.

This time we will introduce the full-color vehicle body intelligent logistics system of Xi’an BYD factory, which was undertaken and constructed by Zhongding Integration in 2019.

About BYD

BYD, founded in 1995, boasts over 30 industrial parks around the world and completes global strategic layout across six continents after rapid expansion over the past twenty years. BYD has its business layout established in such fields as electronics, automobile, new energy and rail transit and plays a critical role accordingly. The overall new energy solution of zero emissions ranging from energy acquisition, storage to application has been completed. BYD has been listed in Hong Kong and Shenzhen Stock Exchange, with turnover and total market value exceeding 100 billion yuan.

1. Safeguard production process with core design

The full-color vehicle body intelligent logistics system designed by Zhongding Integration a subsidiary of NOBLELIFT Group, serves as a connecting link for BYD’s automobile production process. The whole warehouse is between painting workshop and final assembly workshop. It not only temporarily stores semi-finished full-color vehicle body for painting workshop but also ships full-color vehicle body in a real-time manner according to the order of final assembly workshop.

The unmanned logistics links keep warehouse management safe, stable, efficient and precise

Slash business cost via batch painting and economics of scale

2. Emancipate production capacity via intelligent operation and automation

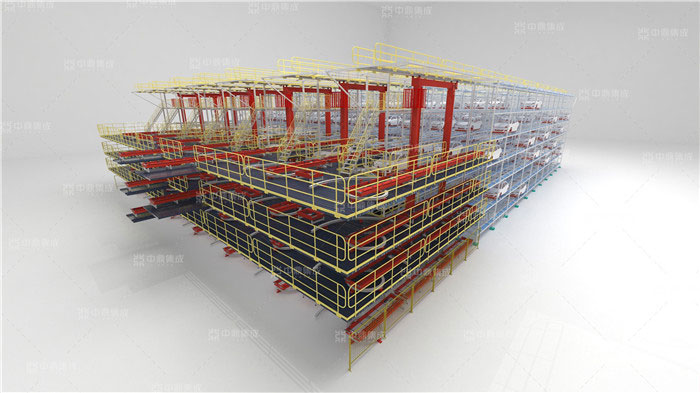

The three-dimensional warehouse of full-color vehicle body, 17.2 meters in height, encompasses storage area and conveying area. The storage area consists of seven aisles, which provides seven double-column stacker cranes by Zhongding Integration, 917 storage locations and 7 maintenance locations. The conveying area contains four layers. The first layer: outbound delivery for final assembly workshop line 2; The second layer: outbound delivery for final assembly workshop line 1; The third layer: inbound delivery for painting workshop line 1; The fourth layer: inbound delivery for painting workshop line 2.

The complete system boasts high efficiency and fast speed. The Takt time is up to 120JPH.

The flexible connection between automated conveyor line and production line makes the unmanned three-dimensional warehouse and workshop available.

The eccentric rotating roller bed is used to convey and reverse vehicle body

3. Directly contact with end users via full-process control

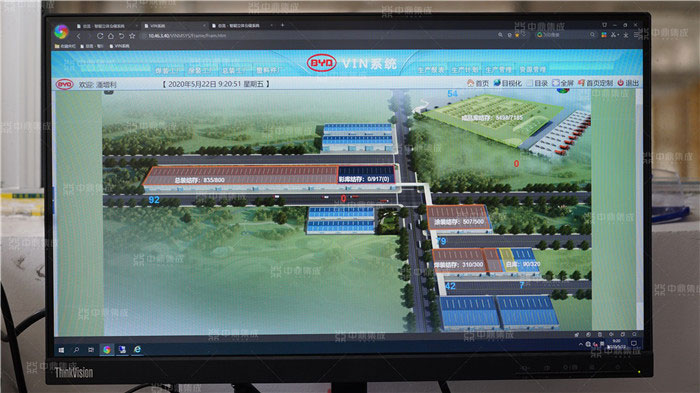

Zhongding Integration specially customizes a complete set of WMS software system for BYD’s logistics process, which can ideally fits its own VIN system, thus controlling the wntire logistics system.

Software interaction: WMS uploads inventory information to VIN while VIN matches inventory information with production plan.

Handy operation: Users directly notify the proposed outbound inventory of in-store vehicle body through VIN, then WMS arranges outbound inventory in the order.

Apart from the concerted efforts to automobile making, Zhongding Integration and BYD forge a close partnership in the field of lithium battery, such as 2014 BYD Shenzhen project and 2018 BYD Qinghai project. They have seen a strategic partnership through mutual growth and development.

BYD Shenzhen

BYD Qinghai

Zhongding Integration, the specialized logistics system integrator, prioritizes the individual development of customer enterprises. Its full-field and full-life cycle intelligent logistics system solution can help clients carry out intelligent upgrade and enhance market competitiveness down the road!