APTIV, previously known as Delphi Automotive (Global Fortune 500), officially split Delphi Powertrain System Division and changed the name in December 2017. Since then, APTIV has been committed to pushing ahead with active safety and autonomous driving as a way to improve driving experience and interconnected services, etc.

APTIV has built a nationwide layout in China since its access to the Chinese market in 1993, including three technology centers and 18 production bases. Over the years, APTIV has been accepted by clients by virtue of its distinguished achievements and won awards from governments and industry because of its great contribution to China's automotive industry.

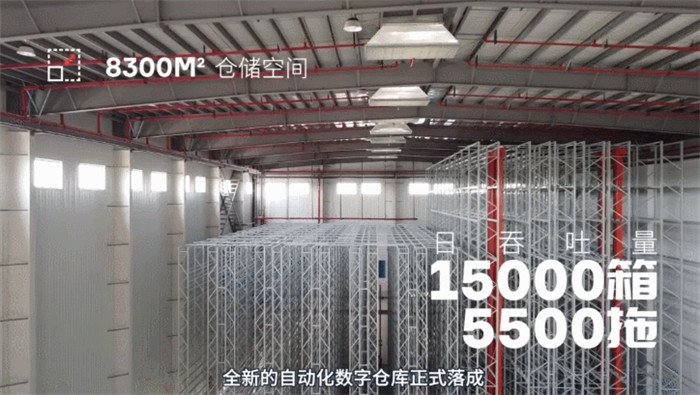

In June 2020, Zhongding Integration, a subsidiary of NOBLELIFT Group got down to the custom fully-automated intelligent warehouse for APTIV’s headquarters in the Asia-Pacific region in response to the logistics demands of Aptiv Electrical Centers (Shanghai) Co., Ltd. Zhongding Integration dominated the plan, design and overall construction of the intelligent warehouse across the board.

Industry of Automotive Parts

Fully-automated Intelligent Warehouse

The intelligent warehouse is equipped with intelligent logistics system (three-dimensional warehousing system, picking and conveyor system, depalletizing and stacking robot system) and logistics software management system (WCS and WMS), which can directly connect with production lines to safeguard smooth supply chain and higher production efficiency by means of automation, digitization, and flexibility.

Diversified Three-dimensional Warehouse Design

Satiate the Demands of Product Storage

According to APTIV’s product category, features and storage requirements, Zhongding Integration divides APTIV’s three-dimensional warehouse into two parts for better logistics efficiency, including pallet warehouse and tote warehouse. By doing so, the logistics needs of 1,200 types of raw materials and 600 types of products can be met. The pallet warehouse is provided with five 22-meter-high double-column and double-deep pallet stacker cranes and 8,530 pallet storage locations.

Tote warehouse is provided with six 16-meter-high double-column, single-station, single-deep pallet high-speed clamp-type stacker cranes and 40,500 tote storage locations.

Advantages of Three-dimensional Tote Warehouse

1. Maximally utilize warehouse. The space utilization of three-dimensional warehouse is almost twice to five times as large as that of ordinary racks.

2. The fully-automated operation effectively extends the service life of tote, which causes fewer damages than manual operation.

3. Higher access efficiency can guaranty well-scheduled chain of production so as to sharply optimize the logistics capability of whole warehouse.

Intelligent Logistics Software Management System

Zhongding Integration customizes WCS and WMS on the basis of APTIV’s demands. The independent information/data management and control system is able to meet APTIV’s requirements of logistics management, such as remote control, warehouse scheduling, data processing and information interaction, etc. The performance of safety, reliability, convenience and extensibility will safeguard APTIV’s growth in the future!

The intelligent logistics system bridges the gap between product and raw material storage and production in the industry, which is a key to stable and efficient operation. At present, the fully-automated intelligent warehouse of APTIV’s headquarters in the Asia-Pacific region has been put into production for more than one year and works well.

Zhongding Integration, a leading logistics system integrator in China, has been devoted to the intelligent logistics for more than three decades. It embraces hundreds of patents and serves such industries as new energy, pharmaceutical, cold-chain transportation, home furnishing products, automobiles, machinery, chemicals, clothing, papermaking and so on. Nearly 900 projects have been completed. In the years to come, Zhongding Integration will make unremitting efforts to improve product quality and software upgrading, thus delivering more benefits for businesses through leading-edge intelligent logistics system solution!