Due to the particularity of drugs, pharmaceutical manufacturing and distribution enterprises have very strict requirements on quality and safety risk control and quality supervision. Logistics system is the most important factor in the entire process of manufacturing and distribution. A professional and standard logistics system is vital to drug quality and operation efficiency of pharmaceutical enterprises.

The case to be introduced here is the intelligent pharmaceutical logistics system jointly built by Zhongding Integration, a subsidiary of Noblelift, and the well-known pharmaceutical company, Chongqing Huapont Pharmaceutical Co., Ltd. (hereinafter referred to as “Huapont Pharm”).

Company Profile

Huapont Pharm, founded in 1994, is a wholly-owned subsidiary of Huapont Life Sciences Co., Ltd. (listed on Shenzhen Stock Exchange, code: 002004). With a registered capital of RMB 450 million and total assets of RMB 3.58 billion, Huapont Pharm operates in a garden-style industrial park spanning over 260 acres, employing more than 1,500 staff members. It holds controlling stakes in several wholly-owned subsidiaries and affiliated companies, including Huapont Shengchem Pharm.

In 2017, due to development needs, Huapont Pharm had to build an intelligent pharmaceutical logistics system that integrates warehousing, transportation and distribution. After careful consideration, Huapont Pharm finally selected Zhongding Integration, a subsidiary of Noblelift, to be responsible for the planning and design of the intelligent warehouse, equipment manufacturing, installation and commissioning.

Pharmaceutical Manufacturing Industry

Solution for Intelligent Pharmaceutical Logistics System

The entire intelligent pharmaceutical logistics system is planned to set up nearly 15,000 storage locations and 10 sets of 22-meter-high Zhongding Integration double-column stacker cranes and over 500 conveyors. The maximum warehousing efficiency can be up to 280 pallets/hour. Zhongding Integration adopted advanced solution planning ideas, technologically-mature automated equipment as well as software management system, and gave new vitality to the complete intelligent logistics system. The project has obtained GMP certification.

Core of Design

Rational Layout Improves Logistics Efficiency

1. The characteristics of pharmaceutical logistics and traditional operating habits were fully considered in the design of technical process. Reasonable layout and simple and smooth process can minimize the amount of ineffective material movement, and improve the system’s processing capacity;

2. Seamless connection of three-dimensional warehouse and each production workshop was realized through the application of corridor conveyor line, effectively reducing the labor intensity of personnel and improving logistics efficiency;

3. All elements, including the process, flow direction, flow rate, flow velocity and carrier of the entire internal logistics met the actual needs of Huapont Pharm.

Entire Process

Intelligent and Flexible

1. Inbound Process

The goods being stacked on pallets are transported by the conveyor system to the inbound port of the corresponding aisle, and put into the designated storage location by stacker cranes of Zhongding Integration.

2. Outbound Process of Raw and Auxiliary Materials/Packaging Materials

After receiving the appropriate instruction, stacker cranes initiate outbound of raw and auxiliary materials/packaging materials. The raw and auxiliary materials are transported to the weighing area for batching by RGV and then transported to the appropriate production workshop through the corridor. The packaging materials are directly transported to the appropriate production workshop through the corridor.

3. Finished Product Conveying & Finished Product Stacking and Inbound in Each Workshop

Finished products from all production lines in each workshop are transported together to the three-dimensional warehouse through the corridor. The transportation path is determined based on requirements of direct stacking or not. If no direct stacking is required, the finished products enter into the temporary storage area for finished products not stacked. Otherwise, after direct stacking, finished products are transported to the robot stacking area for stacking. RGV and stacker cranes by Zhongding Integration then complete the inbound of finished products.

4. Outbound Process of Finished Product

The system will dispatch the goods for outbound according to the outbound instruction. Goods are then automatically transported to the outbound port through the conveyor line.

Meticulous Design

Highlights the Quality of Project

1. Design of stacking and temporary storage: To meet the requirements for temporary storage of finished products during stacking, half-pallet temporary storage is arranged after the robot stacking location. To solve the problem of insufficient length of storage area, the circular line and the stacking sorting line are arranged in layers.

2. Design of high-speed transport and sorting: a direct stacking line is set up. The goods enter the sorting line directly from the main line for sorting and stacking. Without the need of going through the temporary storage line, the operation efficiency can be significantly improved.

3. Redundancy design: In addition to the finished product temporary storage line, an emergency temporary storage line is set up to ensure stable operation of the system.

4. Design of maximum storage locations: Considering the floor layout of the factory, an additional layer of storage locations is set up to make better use of the internal space of the three-dimensional warehouse.

These detailed designs have granted Chongqing Huapont a smoother, more convenient and more efficient logistics experience.

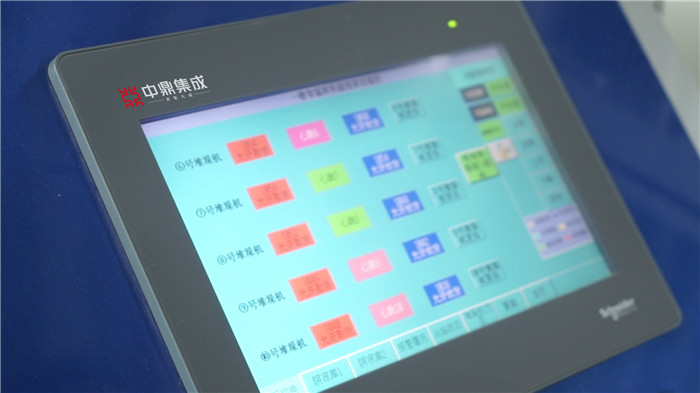

Tailored Software Management System

Based on the process requirements of Huapont Pharm, Zhongding Integration tailored a complete software management system for Huapont Pharm, including WCS warehouse control system and WMS warehouse management system. The system can realize seamless connection with the ERP, MES and LIMIS systems of Huapont Pharm. Through the complete software management system of Zhongding Integration, Huapont Pharm is able to carry out dynamic monitoring and remote management of enterprise logistics operations, achieving full process of unmanned and information-based warehousing operations.

Clean and tidy logistics environment, accurate and fast logistics, as well as maximum use of storage area have significantly reduced enterprise costs... Chongqing Huapont is full of new vitality!

Zhongding Integration has been devoted in the field of intelligent pharmaceutical logistics for over a decade. Considering the features of “two invoices” in the pharmaceutical field, Zhongding Integration has built intelligent warehouses for a large number of pharmaceutical manufacturing, distribution, and device enterprises, including Sinopharm Group, SPH, Yuwell Group, Pien Tze Huang, Shaanxi Tasly etc. In future development, Zhongding Integration will continue the exploration in the field of intelligent pharmaceutical logistics system, continuously improve the quality of software and hardware products, and assist pharmaceutical enterprises to achieve high-quality and sustainable development!