Home logistics is changing in the intelligent era

With the continuous expansion of custom home furnishing market such as wooden doors, wardrobes, and bathrooms in China, all kinds of home furnishing enterprises are developing rapidly. However, while the number of orders is increasing, the logistics pressure is intensifying, and the problems such as high transportation losses, mistakes and omissions, as well as rising logistics costs occur frequently.

In the intelligent era, the logistics model adopted by home furnishing enterprises urgently requires changes. For intelligent home logistics systems, the support for large-scale flexible production and provision of efficient logistics services will become the core functions to maintain competitive power of home furnishing enterprises in the future market competition.

SUPERUS Intelligent Home Logistics System

As one of the Top 10 brands in the wooden door industry in China, SUPERUS Intelligent Home Co., Ltd. (hereinafter referred to as “SUPERUS”) has officially launched the “SUPERUS Intelligent Home Furnishing Factory 4.0” intelligent manufacturing upgrading strategy since 2019 to integrate the Internet, big data and artificial intelligence, and ensure smooth implementation of production, manufacturing, logistics and other related links by digital means.

Zhongding Integration, a subsidiary of NOBLELIFT started cooperation with SUPERUS in January 2020. Based on the characteristics of production process, business forms and logistics characteristics of SUPERUS, Zhongding has tailored a complete set of intelligent home warehousing and logistics system for SUPERUS, which significantly improves the order processing capacity and logistics service level of SUPERUS by changing the logistics model and applying advanced information management systems.

Efficient and flexible logistics processing capacity

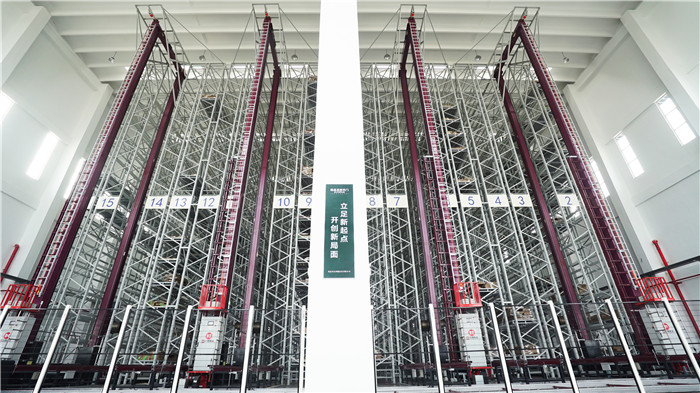

In order to ensure the utilization rate of warehouse space as well as the operation efficiency, Zhongding Integration planned 4 sets of Zhongding Integration double-column double-deep stacker cranes with the height up to 21 meters, 2 sets of RGV rail-guided shuttles and built 4,920 storage locations.

In order to realize intelligent management, Zhongding Integration has equipped the whole intelligent logistics system with an independently developed WMS warehouse management system, to provide SUPERUS with transparent and timely inventory information. It is worth noting that seamless docking between the WMS and the production MES system of SUPERUS may realize real-time data transmission, plan execution, production scheduling and other operations, and greatly improve the fineness of the operations.

1、Inbound

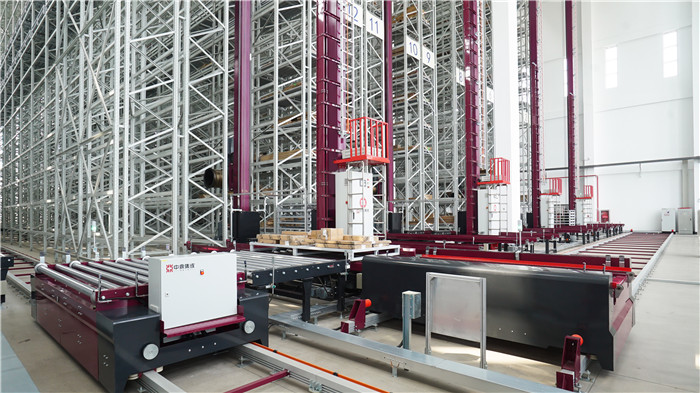

After the finished products are stacked, the operator completes the binding of pallet and product information. Then the stacker cranes complete inbound operations after delivering the products through the code reader, RGV and the designated aisle entrance.

2、Additional inbound

According to the outbound instructions issued by the system, additional pallets are placed at the aisle entrance by the stacker crane and transferred to the additional inbound port by RGV. The operators add foreign materials according to the information displayed on the LED screen and update the number of cargo pallets with RF in hand. WMS automatically completes the update of inventory data based on the results.

3、Whole pallet outbound

The system generates a list of picking storage locations according to the pre-set outbound principle. After being confirmed by the operator, the system generates outbound operation instructions and arrange automatic picking of goods by stacker crane in corresponding aisle to complete outbound.

4、Picking and outbound

The stacker crane places the pallets of finished goods at the aisle entrance, and the conveyor system transports them to the picking and outbound port. The operators then arrange entire box outbound according to the outbound orders.

The system can achieve the following functions for SUPERUS:

High storage: Storage capacity increased by 5 times

High efficiency: inbound/outbound capacity is increased by at least 60%, and 24-hour uninterrupted production can be carried out

High automation: docking with production MES system may realize intelligent management of the whole process

Cost control: saving 80% of land and more than 70% of labour

Zhongding Integration is the first batch of logistics system integrators to deeply explore the field of home logistics. It has summarized a complete set of mature and advanced intelligent logistics system solutions to help users solve logistics problems. In addition to SUPERUS, Zhongding Integration has also successfully built intelligent home logistics systems for many well-known home furnishing companies such as QM, SUOFEIYA and YOUPON Integrated Ceiling.

In the future, Zhongding Integration will continue to work intensively in this field, strive to improve logistics timeliness, improve logistics service capabilities as well as strengthen logistics cost control, and help more home furnishing enterprises easily cope with possible logistics challenges in coming years!