As a technology-driven integrated service provider for the entire pharmaceutical industry chain, Jointown Pharmaceutical Group Co., Ltd. (hereinafter referred to as “Jointown”) is mainly engaged in the big health industries including pharmaceutical circulation, logistics service and healthcare industry. Main six businesses of the company includes digital pharmaceutical distribution and supply chain services, general agency and brand promotion services, pharmaceutical industry and OEM business, digital retail, intelligent logistics and supply chain solutions, health care and technology value-added services.

On November 2, 2010, Jointown was listed on the Shanghai Stock Exchange (stock abbreviation: Jointown, code: 600998). Jointown has remained to be one of the top four enterprises among pharmaceutical business enterprises in China for years. As a leading player of private pharmaceutical business enterprises in China, Jointown ranked 93rd among Fortune 500 (Chinese version) in 2021 and 65th in the list of “China’s Top 500 Private Enterprises”.

For several years, Jointown has established a friendly cooperation relationship with Zhongding Integration, subsidiary of Noblelift. With projects spanning across locations such as Zhengzhou, Wuhan, Hefei, Heilongjiang, Bozhou, among others, Zhongding Integration has earned the trust of Jointown through mature technical expertise, manufacturing capabilities of core equipment, and extensive project construction experience.

In 2020, Zhongding Integration, and Jointown worked together again to build an intelligent pharmaceutical warehouse in Nanning!

Intelligent and Efficient

Pharmaceutical Logistics System

Key and Important Points of the Project

1. The overhead three-dimensional warehouse is located on the second floor of the building, and a basement structure is arranged below the second floor. The project has features of difficult construction and high transportation and lifting requirements.

2. The planning and design should take into account the process, flow direction, flow rate, flow velocity and carrier of Jointown Nanning. It is planned to divide the entire intelligent pharmaceutical warehouse into three operation areas, namely, the rack storage area, the area in front of inbound and outbound area, and the warehousing operation area.

01. Rack Storage Area

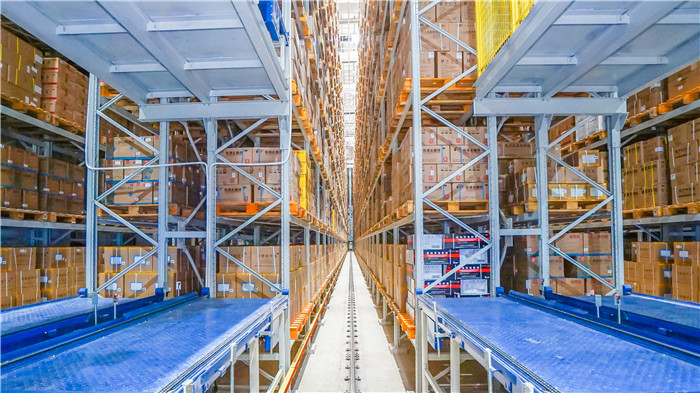

With 7 sets of self-developed stacker cranes by Zhongding Integration and 13,936 storage locations, the 21.5-meter-high rack storage area can fully satisfy the storage demands of Jointown Nanning in current stage and for the future.

02. Area in front of Inbound and Outbound Area

The area in front of the inbound and outbound area is located in the front of the rack storage area. In the area with five layers, each layer may reach conveying efficiency up to 180 pallets/hour, of which the first and second layers are the inbound conveyor line and the outbound conveyor line. In the area, fast and efficient warehousing of whole pallet materials can be performed.

The third lays is set up for online U-shaped picking. For goods that require U-shaped picking, stacker cranes take full pallet of goods for picking and place them on the warehouse end conveyor line. The goods are then conveyed to the manual picking station. Based on the picking task requirements, operators carry out picking of full-pallet goods, take goods and place them on the tote conveyor line behind. The remaining goods on pallet are automatically delivered to the inbound waiting location. Stacker cranes then take them again for inbound. A total of 7 U-shaped picking stations are provided.

The fourth and fifth layers are replenishment conveyor lines set up to respond to the replenishment requirements in real time. Thus, full automated process and seamless connection can be realized!

04. Disassembly and Picking

After completing picking of individual orders in the disassembly and picking area, the totes are sent to the review and packaging area through the conveyor line. Swift transition from tote to paper packaging can be realized and the handling of scattered orders can be performed in a time-saving, efficient and highly accurate way.

05. Warehousing Operation Area

The warehousing operation area is located in the south of the rack storage area (outside the warehouse), and each inbound port there is set up with external dimension detection device and LED display screen, of which the external dimension detection device will trigger alarm if pallet materials with abnormal dimension detection results are found, and the cause of error is displayed on the LED in real time so that the staff can make adjustment promptly based on the information. As a result, the manpower efficiency can be greatly improved!

The pharmaceutical logistics system is intelligent, information-based and flexible, and it may create higher logistics efficiency and reduce the logistics costs for Jointown Nanning!

As a leader in the field of intelligent pharmaceutical logistics, Zhongding Integration serves pharmaceutical companies, pharmaceutical distribution companies, pharmaceutical equipment companies, etc., and it has won the unanimous recognition by pharmaceutical industry leaders such as Shanghai Pharma Group, Sinopharm Group, Jointown, Shaanxi Tasly, Huaren Pharmaceutical and Yuwell Group for its mature and leading intelligent logistics system solutions.

In the future, riding the wave of industry 4.0 and intelligent manufacturing, Zhongding Integration will continue to make unremitting efforts in the field of intelligent logistics, actively develop products independently, promote the intelligent upgrading of more enterprises and move towards the stage of high-quality development!